Introduction

If you're a fleet manager in the US or Canada, you know how time-consuming BIT inspections can be. The BIT Program Truck/Tractor/Trailer Inspection and Maintenance Record Form is required by DOT and FMCSA regulations, but filling it out on paper takes 20-30 minutes per vehicle—and that's if everything goes smoothly.

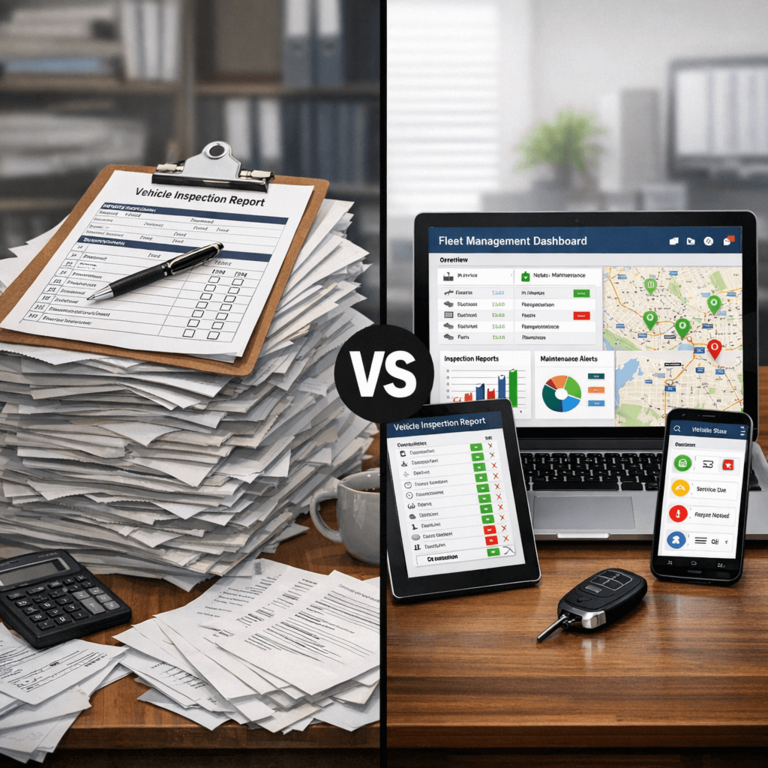

Here's the reality: Most fleets we work with are still using paper forms, and they're losing hours every week to manual data entry, lost paperwork, and stressful DOT audits. When combined with modern pre-trip inspection DVIR software, the BIT inspection and maintenance record becomes easier to complete, store, and retrieve—reducing compliance risk and cutting administrative time by 80%.

This article explains what the BIT Program inspection and maintenance record form is, why it matters, what it includes, and how fleets can manage it more effectively.

Stop Wasting Time on BIT Inspections

In our experience working with 500+ fleet managers across the US and Canada, most fleets spend 20-30 minutes per truck on paper BIT forms. Here's the difference between paper and digital:

| Feature | Paper Forms (Old Way) | PTI4YOU App (New Way) |

|---|---|---|

| Time per Inspection | 20-30 Minutes | 2-5 Minutes |

| Record Storage | Physical Cabinets (Hard to find) | Cloud Storage (Instant Search) |

| Audit Readiness | High Stress, Manual Search | 1-Click PDF Export |

| Error Rate | Illegible handwriting, missing signatures | Zero errors, required fields |

| DOT Compliance | FMCSA §396.11 compliant (if done correctly) | Always compliant, timestamped, signed |

What Is the BIT Program?

The BIT Program (Basic Inspection of Terminals) is a safety compliance program designed to ensure that commercial vehicle terminals maintain safe vehicles and accurate maintenance records. The program focuses on:

- Regular vehicle inspections

- Preventive maintenance programs

- Proper documentation and recordkeeping

- Ongoing driver and vehicle safety oversight

The BIT Program requires fleets to maintain detailed inspection and maintenance records for trucks, tractors, and trailers, including proof that safety defects are identified and repaired in a timely manner.

What Is the BIT Program Truck/Tractor/Trailer Inspection and Maintenance Record Form?

The BIT Program Truck/Tractor/Trailer Inspection and Maintenance Record Form is a standardized document used to track the inspection condition and maintenance history of commercial vehicles. It provides a single, structured record of:

- Vehicle identification information

- Inspection findings

- Maintenance and repair actions performed

- Parts, fluids, and labor used

This form serves as documented proof that vehicles are inspected regularly and maintained according to applicable safety regulations.

Key Information Captured on the BIT Inspection Form

Vehicle and Identification Details

The form records essential identifying information, including:

- Company or contractor name

- Vehicle make, model, and year

- Unit number and serial number

- License plate number

- Odometer reading

- Inspection date and report number

Accurate vehicle identification ensures inspection records can be traced to specific equipment during audits or investigations.

Inspection Categories Covered

Truck, Tractor, and Trailer Interior & Exterior

This section verifies the condition of key safety and visibility components such as:

- Fire extinguisher presence and condition

- Horn, gauges, and speedometer operation

- Mirrors and windshield condition

- Lights, signals, and reflectors

- Electrical wiring and battery connections

Engine and Electrical Systems

Engine and electrical checks help prevent breakdowns and roadside failures. Items typically inspected include:

- Radiator and cooling hoses

- Belts, compressors, and water pumps

- Air and fuel lines

- Engine mounts and visible leaks

- Alternator and starter wiring

Brake Systems

Brake inspections are a critical safety requirement under BIT and DOT regulations. The form includes checks for:

- Brake linings and drums

- Air leaks and pressure tests

- Brake hoses and tubing condition

- Parking and emergency brakes

- Brake adjustment and reservoir levels

Chassis and Structural Components

This section ensures the structural integrity of the vehicle by inspecting:

- Steering gear and steering linkage

- Suspension springs and U-bolts

- Frame rails and cross members

- Drive shaft and universal joints

- Wheel seals and undercarriage condition

Trailer-Specific Inspection Items

The BIT form includes trailer-specific inspection items to confirm safe coupling and operation, including:

- Air and electrical line connections

- Fifth wheel condition and locking mechanisms

- Trailer tires, wheels, and safety locks

- Emergency relay valves and tank mounting

- Mud flaps and fenders

Maintenance, Repairs, and Parts Tracking

A critical section of the BIT Program inspection and maintenance record form documents maintenance activity, including:

- Lubricants and fluids used

- Filters replaced

- Parts and accessories installed

- Labor time and associated costs

This section provides full traceability of maintenance actions and supports preventive maintenance planning.

Why the BIT Inspection and Maintenance Record Form Is Important

Regulatory Compliance

BIT inspections verify that fleets are complying with safety regulations and maintaining vehicles properly. Missing or incomplete records can result in fines, penalties, or vehicles being placed out of service.

Improved Vehicle Safety

Consistent inspections and documented repairs significantly reduce the risk of mechanical failures, roadside breakdowns, and accidents.

Audit and Inspection Readiness

During terminal inspections or compliance audits, fleets must present inspection and maintenance records quickly. Well-maintained BIT forms demonstrate a strong safety culture and operational control.

Challenges of Paper-Based BIT Inspection Forms

Managing BIT inspection records on paper creates several operational challenges, including:

- Lost or damaged paperwork

- Illegible handwriting

- Time-consuming manual audits

- Duplicate data entry

- Limited visibility into maintenance trends

What We Learned from California Fleet Managers About BIT Inspections

Last year, we helped a 50-truck fleet in Fresno switch from paper BIT forms to digital. The fleet manager told us something that stuck with us: "I spent three hours last month just looking for a single BIT form from two weeks ago. The driver swore he turned it in, but we couldn't find it anywhere. When CHP showed up for a random terminal inspection, we had to scramble."

This isn't unusual. Here's what we've learned from working with fleets in California, Texas, and across the border in Ontario:

- The 90-Day Cycle Problem: BIT inspections happen every 90 days, but paper forms get filed by date, not by vehicle. When you need to prove a specific truck was inspected last quarter, you're digging through filing cabinets. One fleet manager in Sacramento told us it took her 45 minutes to find the right form during a CHP inspection—and that was considered "fast."

- Terminal vs. Roadside Confusion: BIT forms are different from daily DVIRs, but drivers mix them up. We've seen drivers fill out a daily inspection form and think it counts as a BIT inspection. When the terminal gets audited, they're missing the actual BIT documentation required under California's Basic Inspection of Terminals program.

- The Signature Fade Issue: Paper forms stored in filing cabinets fade over time. A fleet in Los Angeles lost a $12,000 insurance claim because the signature on a 6-month-old BIT form was too faded to verify. The insurance company argued they couldn't prove who signed it.

- Photo Evidence Matters: When a defect is found during a BIT inspection, you need proof. One fleet manager showed us a paper form where a driver wrote "brake line damaged" but the mechanic couldn't tell which brake line or how severe. With digital BIT forms, the driver takes a photo right there, and the mechanic knows exactly what to fix.

What Changed for Our Fresno Fleet: After switching to digital BIT forms, that same fleet manager can now pull up any vehicle's complete BIT history in under 10 seconds. During their last CHP inspection, they had all records ready in 2 minutes. The inspector was impressed—and that matters for your terminal's safety rating.

Digitizing the BIT Program Inspection and Maintenance Record

Modern fleets increasingly use pre-trip inspection DVIR software and digital maintenance platforms to manage BIT compliance more efficiently.

Digital solutions allow fleets to:

- Complete inspections electronically

- Attach photos of defects and repairs

- Track maintenance history in real time

- Store records securely in the cloud

- Retrieve reports instantly during audits

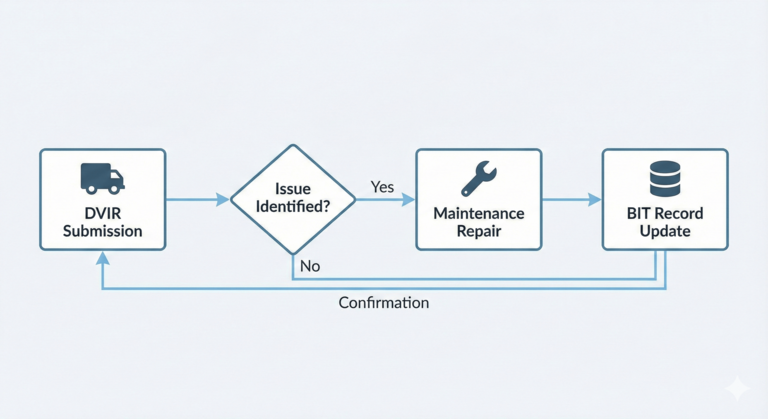

How BIT Forms Work Together with DVIR Software

The BIT Program inspection and maintenance record complements daily pre-trip and post-trip DVIRs to form a complete compliance ecosystem:

- DVIRs identify vehicle defects during daily operations

- BIT records document scheduled inspections and maintenance

- Maintenance logs confirm corrective actions were completed

Best Practices for Managing BIT Inspection Records

Standardize Inspection Processes

Use consistent inspection checklists and procedures across your fleet to ensure uniform documentation.

Retain Records Properly

Maintain inspection and maintenance records for the required regulatory retention period.

Train Drivers and Mechanics

Ensure drivers and maintenance staff understand inspection standards and documentation requirements.

Use Digital Tools

Adopting digital DVIR and inspection software improves accuracy, efficiency, and overall compliance.

Frequently Asked Questions (FAQ)

What is the BIT Program Truck/Tractor/Trailer Inspection and Maintenance Record Form?

It is a compliance document used to record inspections, maintenance, and repairs for commercial trucks, tractors, and trailers as required by the BIT Program and related safety regulations.

Is the BIT inspection form required for DOT compliance?

In jurisdictions that enforce the BIT Program, fleets must maintain inspection and maintenance records. These records are often reviewed during DOT roadside inspections or terminal audits.

How long must BIT inspection and maintenance records be retained?

Retention periods vary by regulation, but fleets are typically required to keep inspection and maintenance records for at least one to two years.

Can BIT inspection records be stored digitally?

Yes. Digital inspection systems and DVIR software allow BIT records to be stored securely in the cloud and accessed instantly during audits.

How does DVIR software support BIT Program compliance?

DVIR software captures daily inspection data, documents vehicle defects, and links them to maintenance actions, making BIT inspection and maintenance records more accurate and audit-ready.

Final Thoughts

The BIT Program Truck/Tractor/Trailer Inspection and Maintenance Record Form is a foundational compliance document for commercial fleets. It proves that vehicles are inspected, maintained, and repaired according to safety regulations.

By combining BIT inspection records with modern pre-trip inspection DVIR software, fleets can reduce risk, improve safety, and streamline compliance management — all while remaining audit-ready and operationally efficient.

For more information about digital DVIR solutions, read our guides: Pre-Trip Inspection DVIR Software: The Complete Guide and What Is a Pre-Trip Inspection and Why Drivers Must Do It.

If you want to digitize your BIT inspection records and streamline compliance, start your 15-Day Free Trial.